The Midmark M11 Service Manual provides essential guidance for installing, operating, and maintaining the M11 Ultraclave․ It ensures safe and efficient sterilization for healthcare professionals․

Key Features of the Midmark M11 Ultraclave

The Midmark M11 Ultraclave features Quiet Door Technology for noise reduction, advanced steam sterilization for efficient cleaning, and fast cycle times, enhancing productivity in healthcare settings․

Quiet Door Technology

The M11 Ultraclave’s Quiet Door Technology minimizes operational noise, creating a quieter environment․ This innovative feature reduces disturbances, making it ideal for busy healthcare settings․ Proper door alignment and regular gasket inspection are crucial for maintaining this function, as outlined in the service manual․ Users should ensure all components are in good condition to preserve noise reduction benefits․ This technology enhances workplace comfort without compromising sterilization efficiency, ensuring smooth operation and patient care․ Regular maintenance, as detailed in the manual, keeps the Quiet Door functioning optimally for long-term performance․

Steam Sterilization Process

The M11 Ultraclave utilizes advanced steam sterilization to ensure effective infection control․ The process involves generating steam under controlled conditions to achieve optimal temperature and pressure․ This method is highly efficient for medical instruments․ The manual details proper cycle parameters and duration for various loads․ Regular maintenance, such as checking steam generator functionality, is essential for consistent performance․ Proper water quality and drainage are also critical to prevent operational issues․ Following the manual’s guidelines ensures reliable sterilization results, maintaining patient and staff safety․

Safety Guidelines and Precautions

Adhere to safety guidelines to ensure proper operation and prevent hazards․ Regularly inspect components and follow maintenance schedules to maintain optimal performance and safety standards․

Safety Precautions for Operation

Ensure all operators are trained and follow safety guidelines․ Regularly inspect the sterilizer for leaks or damage․ Use authorized parts and adhere to maintenance schedules․ Verify performance annually or every 10 years by a Midmark-authorized service provider․ Always follow proper procedures to avoid accidents and maintain sterilization efficiency․ Refer to the manual for detailed instructions and safety protocols to ensure optimal functioning and user safety․ Proper upkeep prevents hazards and extends equipment lifespan․ Adhere strictly to all safety measures outlined in the manual for reliable operation․

Emergency Procedures

In case of power failure, immediately disconnect the unit and contact Midmark Technical Support․ During a system malfunction, avoid opening the door until the cycle completes․ If steam leakage occurs, turn off the power and inspect gaskets․ For any unexpected issues, refer to the manual or contact authorized service providers․ Always prioritize safety and follow proper shutdown procedures to prevent damage or injury․ Ensure all emergencies are handled by trained personnel to maintain equipment integrity and user safety․ Regular inspections can help prevent unexpected operational issues․

Installation and Setup Instructions

Follow the manual for proper installation, ensuring all pre-installation requirements are met․ Complete the step-by-step setup carefully to ensure safe and efficient operation of the M11 Ultraclave․

Pre-Installation Requirements

Ensure the site meets all specified electrical, spatial, and environmental conditions before installation․ Verify the availability of necessary utilities and proper ventilation․ Check for compliance with local regulations and Midmark guidelines․ Confirm the model number and serial number match the manual․ Ensure all components are included and undamaged․ Prepare the area for safe and efficient setup, adhering to Midmark’s installation standards to avoid potential issues during operation․ Proper preparation ensures a smooth and successful installation process for the M11 Ultraclave․

Step-by-Step Installation Process

Begin by unpacking and inspecting all components for damage․ Follow the manual’s layout diagram to position the unit correctly․ Connect electrical and water supplies, ensuring compliance with specified requirements․ Secure the sterilizer to the floor to prevent movement․ Install necessary accessories like the drain kit and water filter․ Perform a power-on test to verify all systems function properly․ Conduct a final inspection and ensure all safety features are activated․ Complete the installation by running a test cycle to confirm optimal performance of the M11 Ultraclave․

Maintenance and Troubleshooting

Regularly clean and inspect the M11 Ultraclave, including filters and gaskets․ Address issues promptly to ensure optimal performance and safety, referencing the manual for detailed guidance․

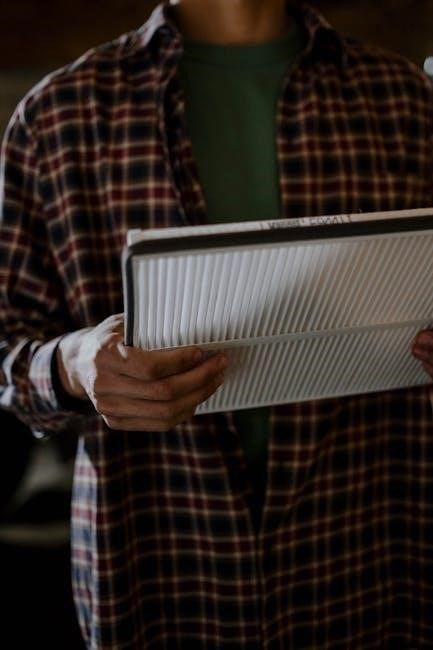

Regular Maintenance Tasks

Regular maintenance is crucial for the optimal performance of the Midmark M11 Ultraclave․ Check door gaskets and seals for wear or damage, ensuring proper alignment and tightness․ Clean the interior and exterior surfaces regularly to prevent residue buildup․ Verify water quality and levels as specified in the manual to maintain sterilization efficiency․ Inspect and replace worn-out components promptly to avoid operational issues․ Schedule periodic performance verification by a Midmark Authorized Service Provider to ensure compliance and safety standards are met․ Consistent upkeep extends the lifespan of the unit and ensures reliable sterilization results․

Common Issues and Solutions

Common issues with the Midmark M11 Ultraclave include door gasket leaks, error codes, and inadequate sterilization․ For door leaks, inspect and replace worn gaskets․ Error codes can often be resolved by restarting the unit or checking sensor connections․ If sterilization fails, ensure proper water quality and verify cycle parameters․ Refer to the troubleshooting section in the manual for detailed solutions․ Addressing these issues promptly ensures reliable operation and maintains the effectiveness of the sterilization process․

Warranty and Technical Support

The Midmark M11 Ultraclave is supported by a comprehensive warranty covering parts and labor for a specified period․ Contact Midmark’s technical support for expert assistance with repairs, parts, and maintenance, ensuring optimal performance and extending the sterilizer’s lifespan․

Warranty Information

The Midmark M11 Ultraclave is backed by a comprehensive warranty covering parts and labor for a specified period․ The warranty ensures that defects in materials and workmanship are addressed, providing peace of mind for users․ To process a warranty claim, contact Midmark’s Technical Service Department with the model number, serial number, and a detailed description of the issue․ Proper maintenance and adherence to guidelines are essential to uphold warranty validity․ Additionally, Midmark recommends periodic verification of the sterilizer’s performance by an authorized service provider every 10 years to ensure compliance and safety standards․

Contacting Midmark Technical Support

For assistance with the Midmark M11 Ultraclave, contact Midmark’s Technical Support via phone or email․ Provide your model and serial number for efficient service․ Fax orders can be sent using the Fax Order Form in the manual․ Warranty-related inquiries require contacting the Technical Service Department directly․ For non-warranty parts, use the designated fax line․ Ensure all correspondence includes necessary details like part numbers and issue descriptions for prompt resolution․ Midmark’s support team is available to address operational, maintenance, and troubleshooting needs effectively․

Downloading the Midmark M11 Service Manual PDF

The Midmark M11 Service Manual PDF is available for download on Midmark’s official website and authorized sources, ensuring easy access to essential information and troubleshooting guides․

Benefits of the Digital Manual

The digital version of the Midmark M11 Service Manual offers convenience and accessibility, allowing users to quickly locate specific sections or procedures online․ It eliminates the need for physical storage, reducing clutter and ensuring the manual is always within reach․ The digital format also enables easy searching, bookmarking, and printing of relevant pages, enhancing efficiency for technicians and healthcare professionals․ Regular updates can be downloaded to keep the manual current, ensuring compliance with the latest safety and operational standards․ This digital accessibility streamlines maintenance and troubleshooting processes, supporting optimal performance of the M11 Ultraclave․

Authorized Sources for Download

The Midmark M11 Service Manual PDF is available for download through Midmark’s official website and authorized distributors․ Ensure authenticity by accessing it directly from Midmark’s technical support or verified partners․ Avoid unofficial sources to maintain compliance with safety and operational standards․ Contacting Midmark’s Technical Service Department is recommended for secure and up-to-date downloads․ This ensures you receive the most current and accurate information for the M11 Ultraclave, supporting proper installation, maintenance, and troubleshooting․ Always verify the source to prevent downloading incomplete or incorrect versions of the manual․

The Midmark M11 Service Manual is an indispensable resource for healthcare professionals, offering comprehensive guidance on installation, operation, and maintenance of the M11 Ultraclave․ By following the manual’s instructions, users can ensure optimal performance, safety, and longevity of the equipment․ Regular updates and adherence to Midmark’s recommendations are crucial for maintaining compliance and reliability․ This manual underscores Midmark’s commitment to providing high-quality, user-friendly solutions for sterilization needs in dental and medical settings, ensuring patient and staff safety remain a top priority․