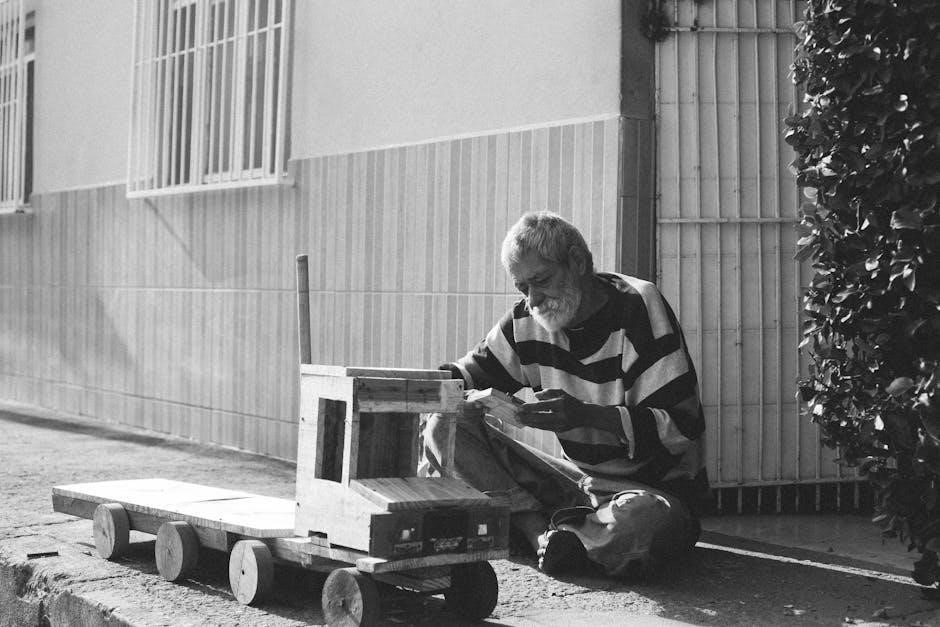

Discover the simplicity of creating a custom truck flatbed using free DIY weld truck flatbed drawings in PDF format. These detailed plans offer clear visuals‚ precise measurements‚ and step-by-step guidance‚ making it easy to transform your vehicle into a versatile workhorse. Perfect for both novice and experienced welders‚ these drawings provide a cost-effective solution for upgrading your truck’s functionality and style. Tailor your flatbed to meet specific needs‚ ensuring durability and practicality for hauling and storage. Start your project with confidence using these accessible and comprehensive resources.

Understanding the Benefits of Building Your Own Flatbed

Building your own flatbed offers significant advantages‚ including customization‚ cost savings‚ and enhanced functionality. With free DIY weld truck flatbed drawings in PDF‚ you can tailor the design to your truck’s specifications and needs. This approach allows for personalization of dimensions‚ material choices‚ and storage solutions‚ ensuring a perfect fit and optimal utility. Additionally‚ it provides an opportunity to improve welding and fabrication skills‚ making the project both practical and rewarding. The ability to customize according to specific requirements enhances the truck’s versatility for work or leisure‚ while cost savings compared to pre-made options make it a financially appealing choice. Overall‚ constructing your own flatbed ensures durability‚ functionality‚ and a sense of accomplishment‚ making it a worthwhile investment of time and effort.

Why Free DIY Weld Truck Flatbed Drawings Are Essential

Free DIY weld truck flatbed drawings in PDF are indispensable for simplifying the fabrication process. They provide clear visuals‚ precise measurements‚ and step-by-step instructions‚ ensuring accuracy and efficiency. These drawings enable customization‚ allowing you to tailor the flatbed to your truck’s specifications and needs. By offering detailed plans‚ they make the project more manageable‚ even for novices. This cost-effective resource saves time and money‚ helping you achieve professional-grade results without the expense of pre-made designs. Essential for both skilled fabricators and DIY enthusiasts‚ these drawings empower you to create a durable‚ functional flatbed that meets your exact requirements.

Where to Find Free DIY Weld Truck Flatbed Drawings in PDF

Easily find free DIY weld truck flatbed drawings in PDF online. Websites‚ forums‚ and communities offer a variety of designs for different truck models and uses.

Top Websites Offering Free Downloadable Plans

Popular websites like Pro-Mechanics & Fabrication‚ WeldingWeb‚ and Instructables provide free DIY weld truck flatbed drawings in PDF. These platforms offer a variety of designs‚ from simple to complex‚ catering to different truck models and uses. Many forums and communities also share user-generated plans‚ ensuring a wide range of options for customization. These resources are ideal for both novices and experienced fabricators looking for detailed guidance and inspiration.

How to Verify the Accuracy of the Drawings

To ensure the drawings are accurate‚ compare the dimensions with your truck’s specifications and intended use. Check that the plans match your truck model and requirements. Review the material lists and welding techniques for compatibility with your tools and skills. Consult online forums or experienced fabricators for feedback. Verify that the drawings include clear assembly instructions and safety guidelines. This step ensures a well-fitted and durable flatbed design tailored to your needs.

Tools and Materials Needed for the Project

Essential tools include a welding machine‚ angle grinder‚ measuring tape‚ wrenches‚ and hand tools. Materials like steel tubing‚ decking‚ and fasteners are required for durability and stability.

Essential Welding Tools for Fabrication

A MIG‚ TIG‚ or stick welder is crucial for strong‚ precise welds. An angle grinder with cutting and grinding discs is necessary for preparing metal. A measuring tape‚ level‚ and square ensure accuracy. Clamps are vital for holding pieces in place during welding. Safety gear like a welding helmet and gloves is non-negotiable. Additional tools include wrenches‚ sockets‚ and pliers for assembly. Ensure all equipment is in good condition for a successful fabrication process.

Best Materials for a Durable Flatbed

Steel tubing or C-channel is ideal for the frame due to its strength and weldability. Sheet metal or diamond plate is recommended for the decking‚ offering durability and slip resistance. Aluminum is lightweight and corrosion-resistant but less strong. Treat all steel with primer and rust-resistant coatings for longevity. Wood decking is cost-effective but requires maintenance. Choose materials based on intended use‚ ensuring a balance between strength‚ weight‚ and cost for a durable flatbed.

Measuring Your Truck for a Custom Fit

Measure your truck’s frame length and width accurately‚ considering overhang and rear clearance. Ensure precise dimensions for a secure‚ functional fit tailored to your vehicle’s specifications.

How to Accurately Measure Your Truck Bed Dimensions

Measure the truck’s frame length from the cab to the rear‚ ensuring proper overhang and clearance. Record the width between the frame rails for a flush fit. Note the height to maintain functionality and appearance. Use a level and square for accuracy‚ ensuring all dimensions align with your flatbed design. Double-check measurements to avoid errors. Proper alignment with existing mounting points guarantees a secure and functional fit.

Considerations for Overhang and Clearance

Ensure the flatbed’s overhang does not obstruct rear visibility or exceed legal limits. Measure clearance around wheels and suspension to prevent interference. Consider turning radius and parking space constraints. Proper overhang and clearance ensure safe operation‚ prevent damage‚ and maintain compliance with regulations. Plan carefully to avoid costly modifications and enhance overall functionality for hauling and transportation needs.

Constructing the Frame

Building a sturdy frame is crucial for your flatbed’s structural integrity. Use steel tubing or C-channel for strength‚ ensuring precise cuts and alignment with your truck’s dimensions.

Step-by-Step Guide to Building the Frame

Start by measuring your truck’s frame to determine the flatbed’s dimensions. Cut steel tubing or C-channel according to your DIY drawings. Assemble the frame by aligning the pieces and ensuring squareness. Use clamps to hold components in place before welding. Tack weld each joint‚ then complete full welds for strength. Allow the frame to cool‚ then reinforce critical joints with additional welds or gussets for added durability and stability.

Welding Techniques for Structural Integrity

Ensure structural integrity by using proper welding techniques. MIG welding is ideal for speed and ease‚ while TIG welding offers precision for thinner materials. Clean surfaces thoroughly before welding to remove rust and grease. Use appropriate voltage and amperage settings for strong‚ penetration-rich welds. Employ stitch welding to distribute heat evenly and prevent warping. After welding‚ allow the frame to cool gradually to avoid stress cracks. Inspect welds for defects and reinforce joints with gussets for added strength and durability.

Selecting the Right Decking Material

Choose between wood‚ steel‚ or aluminum for your flatbed decking. Wood offers a classic look and traction‚ while steel provides strength and durability. Aluminum is lightweight and corrosion-resistant‚ ideal for sleek‚ long-lasting solutions. Each material offers unique benefits‚ ensuring a tailored fit for your truck’s specific needs and intended use.

Wood vs. Steel vs. Aluminum: Pros and Cons

Wood decking offers a classic look‚ good traction‚ and cost-effectiveness but requires regular maintenance and is prone to rot. Steel decking is durable‚ strong‚ and ideal for heavy-duty use but is heavier and may rust if not properly treated. Aluminum decking is lightweight‚ corrosion-resistant‚ and sleek but more expensive and less strong than steel. Each material has unique advantages and disadvantages‚ so consider your specific needs and preferences when choosing the best option for your flatbed.

Installation Tips for a Secure Decking Surface

Ensure a secure decking surface by cleaning and preparing the frame before installation. Align the decking material precisely with the frame‚ using clamps to hold it in place. Secure the decking with bolts or screws‚ tightening evenly to avoid warping. Check for any obstructions and ensure the surface is level. Apply a rubber sealant between the decking and frame for weatherproofing. Torque bolts according to specifications for maximum durability and safety.

Assembly and Finishing Touches

Mount the flatbed securely to the truck frame‚ ensuring alignment and stability. Add custom features like storage boxes or tie-downs for functionality. Sand‚ prime‚ and paint the surface for a durable finish‚ protecting it from rust and wear. Final inspections ensure all components are securely fastened and the flatbed is ready for use.

Mounting the Flatbed to the Truck Frame

Mounting the flatbed to the truck frame requires precise alignment and secure bolting. Ensure the flatbed is properly positioned and aligned with the truck’s frame rails. Use high-strength bolts and washers to secure the flatbed‚ tightening them evenly to avoid warping. Double-check the alignment and torque specifications for a safe and durable installation. This step ensures the flatbed is firmly attached and ready for use.

Adding Custom Features and Storage Solutions

Add functionality with custom features like toolboxes‚ tie-down points‚ and lighting. Incorporate storage compartments tailored to your needs‚ ensuring durability and accessibility. Use hinges and latches for secure access and consider materials like aluminum or steel for strength. These enhancements improve organization and versatility‚ making your flatbed more practical for work or leisure. Customizing your storage solutions ensures everything has its place‚ maximizing space and efficiency.

Safety Tips and Best Practices

Always wear protective gear like welding helmets and gloves. Ensure proper ventilation and follow welding procedures to prevent accidents. Inspect all welds for defects and secure the flatbed firmly to the truck frame for stability. Regularly check for rust or damage and address issues promptly to maintain structural integrity. Safety should never be compromised during fabrication and use.

Ensuring Safety During Welding and Fabrication

Always wear protective gear‚ including welding helmets‚ gloves‚ and safety glasses‚ to prevent injuries from sparks and debris. Proper ventilation is crucial to avoid inhaling fumes. Use fire-resistant curtains or screens to contain sparks. Ensure all tools‚ like welders and grinders‚ are in good condition and follow manufacturer guidelines. Regularly inspect welds for defects and address them promptly; Keep a fire extinguisher nearby and maintain a clean workspace to minimize hazards. Prioritize safety to avoid accidents during fabrication.

Post-Construction Inspection and Testing

After completing your flatbed‚ conduct a thorough inspection to ensure all welds are secure and the structure is sound. Check for any signs of warping‚ rust‚ or weak points. Test the load capacity by gradually applying weight‚ observing for any flex or instability. Ensure all bolts and fasteners are tightened properly and the decking is securely attached. Verify that the flatbed aligns perfectly with the truck frame and meets safety standards. This step is crucial for ensuring durability and reliability.

Troubleshooting Common Issues

Address common issues like warping‚ rust‚ or structural weakness by reinforcing welds and treating surfaces. Regular inspections and timely repairs ensure long-term durability and safety.

Addressing Warping‚ Rust‚ and Other Challenges

Warping can occur due to uneven heating during welding. To fix this‚ ensure even heat distribution and use clamps to maintain alignment. Rust can be prevented with primer and sealants. Regular inspections and timely repairs are essential. Other issues like loose fasteners or stress cracks should be addressed promptly. Reinforce weak points and apply protective coatings for long-term durability. Proper maintenance ensures your flatbed remains stable and functional over time.

Repairing and Reinforcing the Flatbed

Repairing and reinforcing your flatbed involves identifying weak spots and addressing structural damage. Weld cracks or gaps promptly to maintain integrity. Use steel plates or gussets to strengthen areas under stress. Apply rust-resistant coatings to protect metal surfaces. Regularly inspect and tighten fasteners to prevent loosening. Reinforce the frame with additional supports if needed. Proper repair techniques ensure your flatbed remains durable and safe for heavy-duty use‚ extending its lifespan and reliability.

Cost Savings and Budgeting

Building a DIY flatbed offers significant cost savings compared to buying pre-made options. Utilize free PDF drawings to minimize expenses without compromising quality. Control your budget by sourcing materials strategically‚ ensuring a cost-effective yet durable result. This approach allows you to allocate resources efficiently‚ achieving a professional-grade flatbed at a fraction of the cost of commercial alternatives.

How to Minimize Expenses Without Compromising Quality

Minimize expenses by sourcing materials like steel tubing and sheet metal locally or in bulk. Use free DIY weld truck flatbed drawings in PDF format to ensure precise measurements and reduce waste. Opt for cost-effective welding tools and consider second-hand equipment. Prioritize durable materials and efficient techniques to maintain quality while staying within budget. Proper planning and execution help achieve a professional-grade flatbed without overspending.

Comparing DIY Costs to Pre-Made Flatbeds

DIY flatbed projects often cost significantly less than pre-made options‚ with materials like steel tubing and sheet metal being affordable. Free PDF drawings help minimize waste and ensure precise cuts‚ reducing expenses. Pre-made flatbeds can range from $1‚200 to $2‚000 or more‚ while DIY builds typically cost $500 to $1‚000‚ depending on materials. Customization and quality remain intact‚ making DIY a budget-friendly choice for those willing to invest time and effort.

Building a custom truck flatbed using free DIY weld truck flatbed drawings in PDF format is a rewarding project that offers cost savings‚ customization‚ and empowerment. Embrace the challenge and create a durable‚ tailored solution for your hauling needs‚ enjoying the satisfaction of a job well done and a long-lasting solution for your truck.

Final Thoughts on Building Your Own Flatbed

Building your own truck flatbed using free DIY weld truck flatbed drawings in PDF format is a satisfying and empowering project. It allows you to customize the design to fit your needs‚ save money‚ and enhance your truck’s functionality. With detailed plans and proper tools‚ you can create a durable and functional flatbed that stands the test of time. Embrace the challenge‚ enjoy the process‚ and take pride in your handmade upgrade!

Encouragement to Start Your DIY Project

Embark on your DIY flatbed project with confidence! Free PDF drawings provide a clear roadmap‚ making the process manageable and enjoyable. With basic tools and skills‚ you can create a custom flatbed tailored to your needs. The sense of accomplishment and pride in your handmade upgrade will be rewarding; Don’t hesitate—start your project today and transform your truck into a versatile‚ functional workhorse that reflects your creativity and skill!